Vieira´s Mills is a leading manufacturer of high-quality, high-performance grinding screens. Our mill screens are used by industries throughout Latin America, guaranteeing our customers the highest quality of the final products they grind.

We are committed to customer satisfaction and offer customized solutions, from the manufacture of the sieves to the rapid delivery of orders, meeting the specific needs of each industry.

Our mill screens are used to grind grains, seeds, spices and so on. These milling screens are essential for ensuring that food products are uniform and of high quality.

Our mill screens are used to grind feed ingredients such as grains and pre-mix formulations. The milling screens we manufacture help to ensure that pet food is nutritionally balanced and tasty in Latin America’s leading pet food industries!

Our mill screens are used to grind various chemical products within the cosmetics industry. The grinding sieves manufactured by us help to ensure that the main cosmetics industries have safe granulometric standards in their processes.

Our mill screens are used to grind ingredients for medicines, such as plants, herbs and chemicals. They help ensure that medicines are safe and effective. We serve these industries by manufacturing the sieves / perforated plates in 316L steel.

Our mill screens are used to grind the most diverse products. As we are manufacturers of perforated plates, we can meet your needs, whether in 1020 Carbon Steel or 304/316L Stainless Steel. Contact our team and ask for more information!

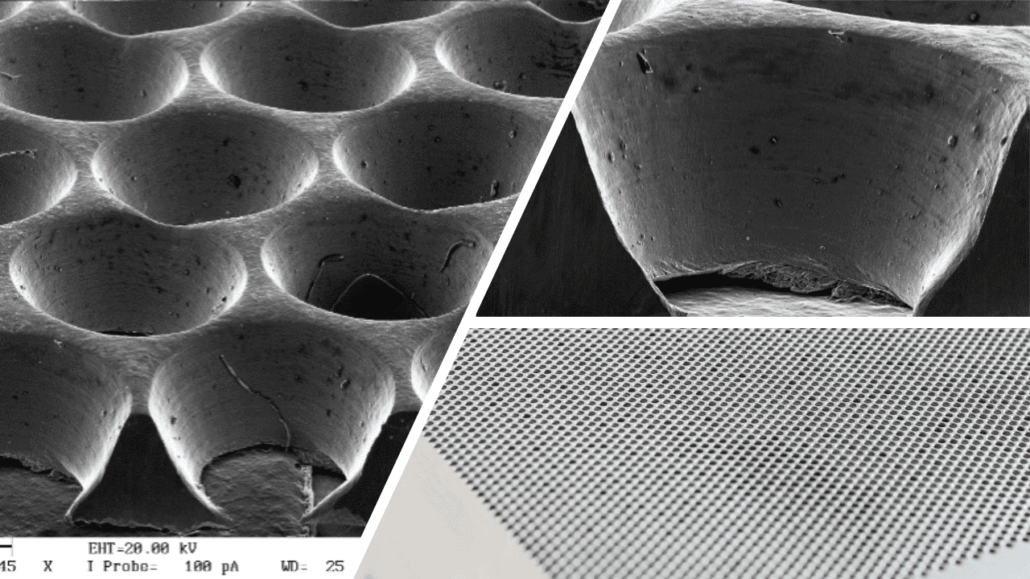

Vieira´s specializes in the manufacture of perforated plates or conical hole screens. These sieves are designed with holes starting at 0.3 mm and are produced in plates with thicknesses greater than the diameter of the holes, which allows for greater durability against wear and abrasion during grinding.

In conical screens, the determining factor for increasing the flow rate in the grinding stream is related to the “Venturi” effect, thus increasing production by 8% to 15% more per hour!

10% to 20% more fines in the granulometry

2.5 to 4 times more durable than conventional screens on the market

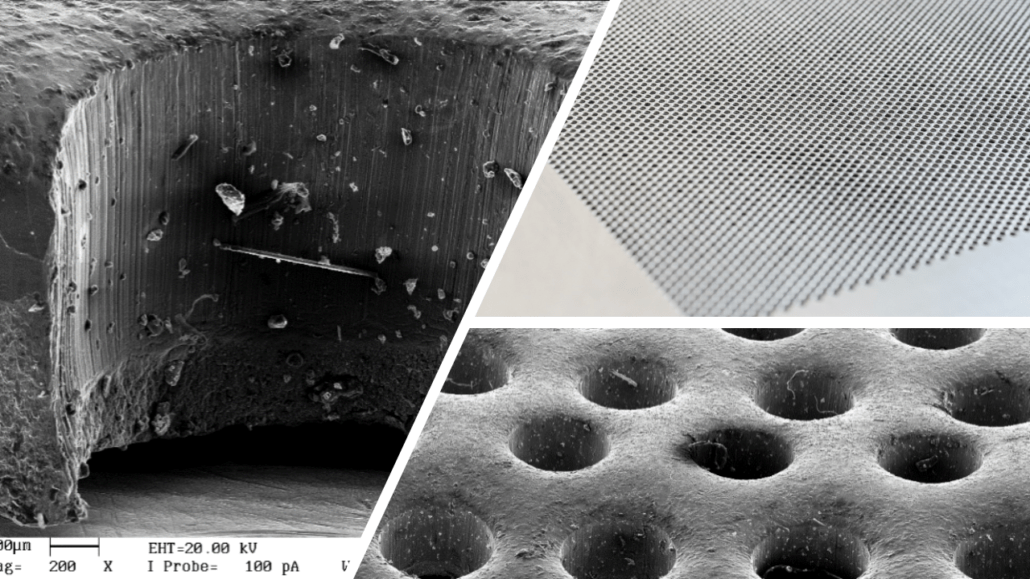

Vieira´s specializes in the manufacture of perforated plates or parallel hole screens. These sieves are designed with holes starting at 2.0 mm and are produced in plates with thicknesses greater than the diameter of the holes, which allows for greater durability against wear and abrasion during grinding

Parallel Screens are manufactured hole by hole, and adjusting the distance between holes allows for a considerable gain in open area, where we can achieve up to 50%!

Due to the heat treatment that the perforated plate undergoes, we increase the wear resistance of the surface layer and improve the fatigue resistance of the screen.

As your production will increase due to the greater open area flow, you will produce more with the same installed power and due to the greater durability, you will achieve less set-up when changing screens, resulting in a considerable reduction in the number of starts on your mill’s electric motor.

The drawing below illustrates a 3D cross-section of what we call screens, or perforated plates. In hammer milling, the granulometric variation of the processed products is determined by the diameter of the conical hole in the screen.

Perforated plates with conical holes or conical screens for mills have been developed to give greater resistance, thus allowing them to be produced in plates with thicknesses greater than the diameter of the holes.

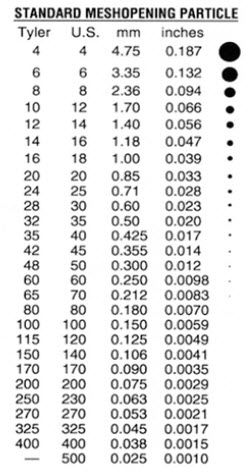

Today, our hammer mills can be used to obtain extremely fine grain sizes, using conical screens starting at 0.3 mm, where the final processed product can reach 90 to 100 MESH. Everything will depend on the product to be processed and its physical characteristics.

With the right technical knowledge, our team can help you find the best result for grinding your product. Contact us!

We specialize in the manufacture of perforated grinding plates, also known as mill screens. Check out the holes we drill below:

We are the only Brazilian mill manufacturer that produces mill screens

Mill screens are perforated plates that, when coupled to a grinding rotor, make it possible to obtain granulometric patterns, helping to micronize and homogenize the desired product.

It is one of the most important spare parts for those who work with hammer mills, as hammer milling is widely used in the human food or animal feed industry because it is very cost-effective, as well as being easy to handle and install.

The mills manufactured by Vieira´s use conical and parallel perforation screens throughout their range of equipment. Depending on the application, these perforated plates can be made from 1020 carbon steel, stainless steel (304 and 316L) and even undergo various heat treatments for greater durability against abrasive wear, thus enabling the screen to have a longer service life.

Moinhos Vieira has its own conical and parallel perforation technology, because we believe that this way we will maintain the standard for our customers, always bringing the best cost-benefit ratio to the milling industry.

The Mesh Conversion Table is a useful reference in hammer mill grinding, used to determine the size of the particles resulting from the process. It relates the Mesh number (a particle size measurement system) to the diameter of the mill’s screen openings. The higher the Mesh number, the smaller the size of the particles produced. This table helps with the choice of screen and the precise configuration of the mill to achieve the desired particle size in the final product, and is essential for industries that require particle size control, such as in the production of animal feed, flour, and other milling applications.

No mercado de máquinas industriais desde 1948, hoje a Moinhos Vieira está presente nas principais indústrias alimentícias, cosméticas e farmacêuticas do Brasil e da América Latina.